English

Views: 90 Author: Site Editor Publish Time: 2024-08-05 Origin: Site

The concept of AI PC was first proposed in September 2023. With the launch of AI PCs or AI compatible PC terminals by major manufacturers, the heat dissipation function has begun to provoke people's thinking. Heat dissipation is the guarantee for the performance release of AI PCs. The heat dissipation performance directly determines the stability and reliability of PC performance. Among the main failure modes of electronic devices, 55% of failures are caused by excessive temperature. The failure rate of electronic components increases exponentially with the increase of operating temperature. For every 10 ℃ increase in temperature, the system reliability decreases by 50%. Therefore, the heat dissipation capacity of PC has become one of the key factors affecting overall performance.

Due to the increase in chip computing power, the requirements for heat dissipation will also increase, but at the same time, it is necessary to meet the overall design requirements of laptops in terms of weight, thickness, and other aspects. Currently, the heat dissipation solutions of various AI PC manufacturers are not completely consistent, but the overall idea of reducing heat generation by improving heat dissipation capacity is consistent.

The main components and materials used are as follows:

Thermal interface material: widely used in all heat dissipation modules, it is used to fill the small gaps and uneven holes on the surface of electronic materials during contact with the heat sink, accelerate thermal energy conduction, transfer chip thermal energy to the heat dissipation fins, reduce chip temperature, improve chip life and product performance. The types of thermal interface materials include thermal conductive silicone film, thermal conductive tape, thermal conductive paste, thermal conductive adhesive paste, etc. The core differences between different materials lie in thermal conductivity, material reliability, voltage resistance, soft hardness, and so on.

Heat pipe: designed using the principles of material vapor and liquid two-phase changes, as well as convection. The main characteristic of heat pipes is rapid temperature equalization, and they are the most commonly used and efficient thermal conductive components in electronic product heat dissipation devices. They have a wider range of applications and a higher popularity rate, and are widely used in various heat exchangers, coolers, and other devices. Heat pipes are generally made of pure copper, presenting a flat and hollow shape, filled with condensate, and responsible for transferring the conducted heat to the fan side at the other end. AI PCs may need to increase the number of heat dissipation copper pipes.

Vapor Chamber: VC is the fundamental component for two-phase heat transfer. The heat transfer capability of the heat spreader adopts a planar format for two-phase cooling, which can quickly transfer high-temperature point heat sources to a large area for heat dissipation. Its function and working principle are the same as that of a heat pipe, and it is driven by the evaporation, condensation, and circulation of fluid enclosed in a plate-shaped cavity. Due to the increase in chip power and the reduction in chip size, the overall power density has increased. Compared to heat pipes, the application of flat temperature equalization plates makes their thermal conductivity faster and more uniform. In principle, the heat conduction mode of a heat pipe is one-dimensional, which is a linear heat conduction mode, while the heat conduction mode of a heat spreader is two-dimensional, which is a surface heat conduction mode. In addition, due to the flat shape of the heat exchanger, it can be made into complex curved shapes, while the heat pipe can only be made into straight or bent pipes. Moreover, the heat dissipation fins that can be installed on the heat exchanger are relatively more than those on the heat pipe, so the heat transfer is greater.

Cooling fan: Cooling fans have become an important component of various cooling products. In the cooling module, the cooling space is limited, and fans can achieve the function of forced air convection to dissipate heat. By designing different fan blades, air flow is generated during fan operation, creating strong wind pressure, reducing the temperature of operating equipment, maintaining stable clock frequency of electronic products, and avoiding equipment performance degradation caused by heat loss. Fans are usually fixed in quantity and respond to heat dissipation needs by increasing their speed.

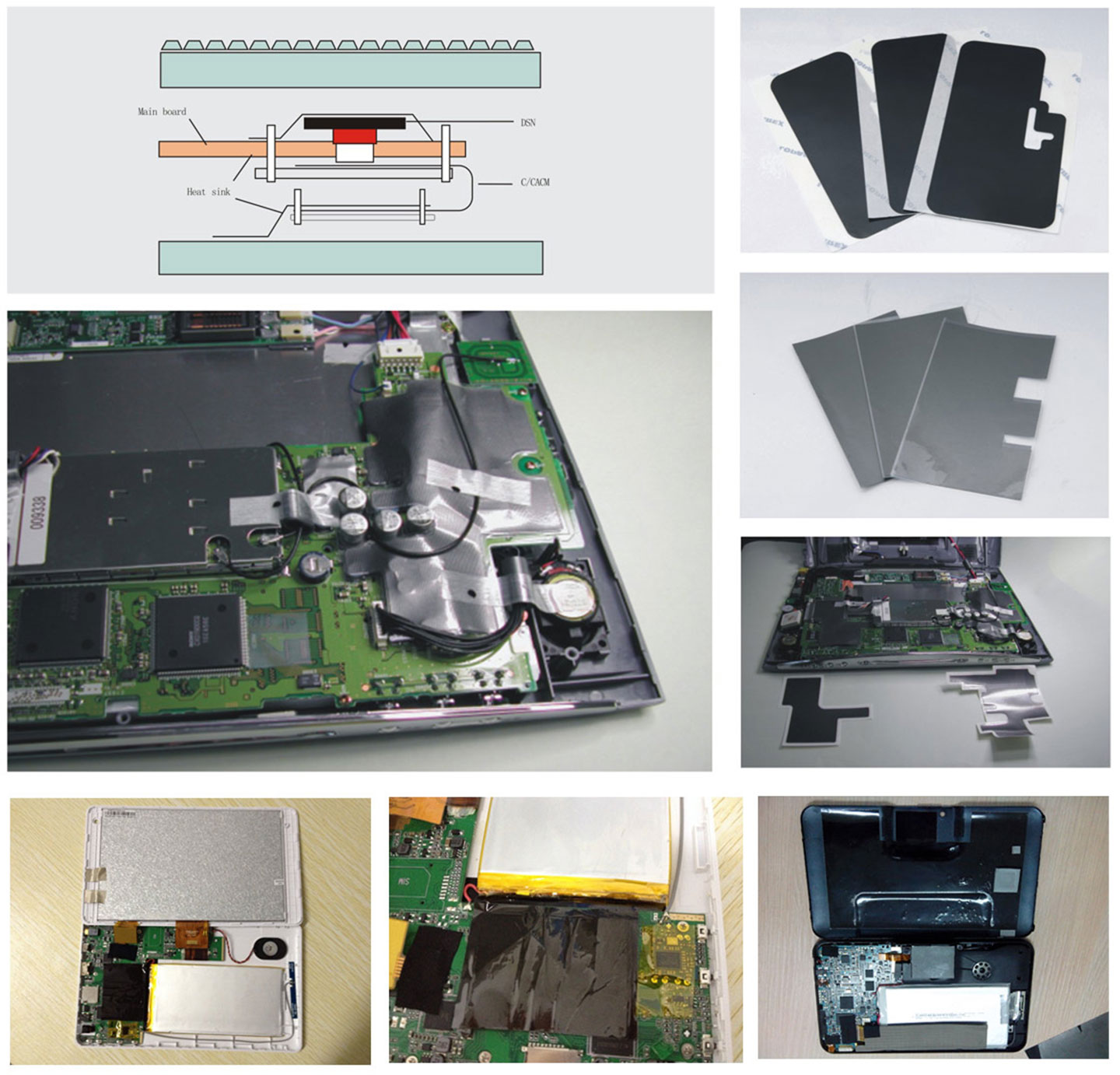

Among them, graphite film is made from polyimide film as raw material, which is carbonized, graphitized and rolled. We also call it artificial graphite paper. Depending on the product form, DSN sells graphite film including graphite roll, graphite sheet and customized graphite sheet. Among them, graphite coil is a semi-finished form and needs to be further cut by customers before use. Graphite sheets are generally finished products after die-cutting and can be directly applied to electronic products.If you buy pyrolytic graphite sheet, welcome your inquiry. Now smartphone graphite sheet is the main application in the world.

Artificial graphite paper has flexibility, high and low temperature resistance, chemical stability, and good horizontal heat transfer ability. It has strong thermal diffusion ability in the horizontal direction and has high application value in eliminating local hotspots, smoothing temperature gradients, and changing the direction of heat flow in miniaturized intelligent electronic devices.

Artificial graphite paper is mainly used in the consumer electronics industry for smartphones, laptops, LCD displays, wearable devices, and other fields. Heat quickly diffuses horizontally through the graphite film, forming a large thermal conductive surface area, effectively transferring heat and improving device heat dissipation efficiency.

Among the above heat dissipation solutions, with the continuous development of consumer electronic products towards high performance, multifunctionality, and slimness, the demand for heat generation and dissipation of internal components in consumer electronic products represented by smartphones, laptops, and smart projectors has significantly increased. Heat pipes and temperature equalization plates are being adopted by more and more consumer electronics brand manufacturers due to their excellent thermal conductivity, and their penetration rate is constantly increasing.