English

Views: 411 Author: Site Editor Publish Time: 2023-11-06 Origin: Site

Due to the advantages of extremely high flexibility and low cost brought about by adapting the roll-to-roll printing process, Printed paper batteries have unique application value in many fields. Printed paper batteries are widely used in active/semi-active RFID smart labels, wearable devices, and iontophoresis masks.

Zinc-Manganese Paper Battery - Paper Battery

The name paper battery comes from the fact that it is produced using a printing process that can achieve a thickness as thin as paper, and its electrochemical system remains the traditional zinc manganese system.

Paper Battery Principle

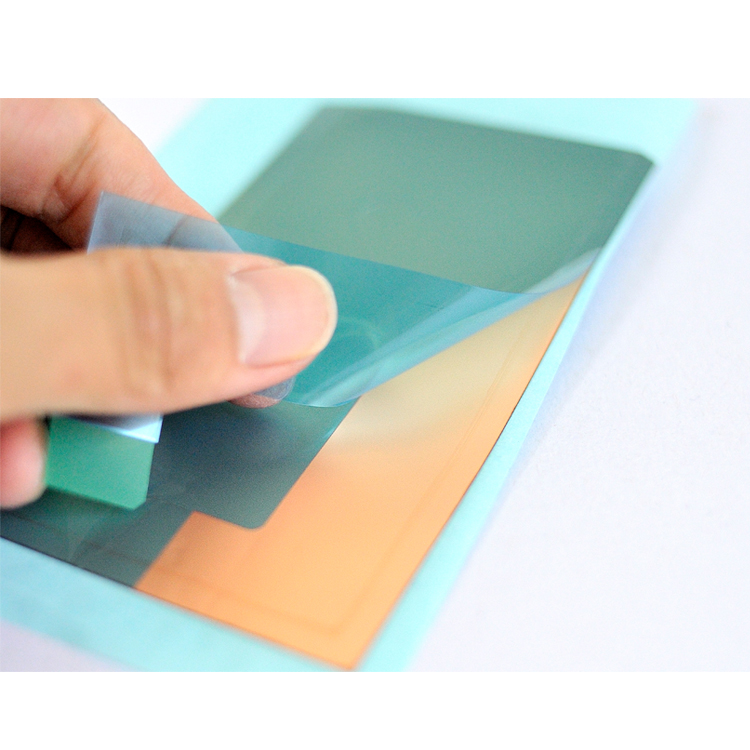

Paper batteries are based on the principle of conventional zinc-manganese acid batteries and are designed to be less than 1 mm thick, with the thinnest being less than 0.5 mm, as shown in the figure.

Unlike conventional batteries, in order to achieve flexibility, the electrochemical active ingredient must be slurried, inked and have a low drying temperature for deposition on a flexible substrate.

Composition of thin film paper batteries

As a new form of battery, paper batteries play a certain complementary role to traditional column and button batteries. There exists great value in potential applications in the Internet of Things, wearable devices, disposable medical electronic devices and ion-introduction masks.

In order to cooperate with the development of flexible paper batteries, Dasen's flexible graphite sheets have been improved in performance and have been applied to paper batteries, receiving good feedback from customers.

Graphite sheets are ideal for paper battery applications because of the following properties, both thermal and electrical conductivity:

1. Graphite paper easy processing: graphite paper can be die-cut into different sizes, shapes and thicknesses, can provide die-cut flat board, thickness can be from 0.05 to 1.5m.

2. High temperature resistance of graphite paper: graphite sheet can be used at a maximum temperature of 400℃ and a minimum temperature below -40℃.

3. High thermal conductivity of graphite paper: the in- thermal conductivity of graphite paper can reach a maximum of 1500W/mK, and the thermal resistance is 40% lower than aluminium and 20% lower than copper.

4. Graphite paper flexibility: graphite paper is easy to make laminates with metal, insulation or double-sided adhesive to increase the flexibility of the design, can add adhesive on the back.

5. Graphite paper lightness: graphite paper is 30% lighter than the same size of aluminium and 80% lighter than copper.

6. The usability of graphite paper: The graphite film can smoothly adhere to any flat or curved surface.

Because graphite contains free-moving electric charges, it conducts electricity because the charges move freely when it is energized , creating an electric current. In addition to paper-chip zinc-manganese batteries, graphite sheets also have important applications in other battery manufacturing. In lithium-ion batteries, for example, graphite foils can be used as a conductive agent in the anode of the battery to improve the cycle stability and capacity retention of the battery. At the same time, graphite foils can also be surface-modified to enhance their electrochemical performance in lithium-ion batteries.

Graphite sheets can also be composited with other materials to form composites with better performance. For example, composites of graphite foils and polymers can be used to flexible electronic devices. Graphite sheets and metal composites have excellent electrical conductivity and mechanical properties, and can be used in the space and automotive industries.

As an important two-dimensional material, graphite sheets have a wide range of application prospects. In the future, the application of graphite sheets will receive more attention and research in the fields of energy, environment, electronics and materials.

If you need heat dissipation materials or thermal solutions, please feel free to contact us.