English

Views: 0 Author: Site Editor Publish Time: 2026-02-14 Origin: Site

You want to know which material is stronger and lighter. Carbon fiber vs aluminum is a debate you must think about for 2026. Carbon fiber has a better strength-to-weight ratio. You see carbon fiber tubing is stiffer for its weight than aluminum. You find carbon fiber parts are about 40–45% lighter than aluminum. DASEN’s carbon fiber products show new levels in performance and innovation. You notice carbon fiber vs aluminum is important in bikes, cars, and electronics.

Carbon fiber vs aluminum means you get:

Carbon fiber density: 1.6 g/cm³

Aluminum density: 2.7 g/cm³

Carbon fiber vs aluminum gives higher tensile strength, up to 6,000 MPa for carbon fiber, around 572 MPa for aluminum.

Property | Carbon Fiber | Aluminum |

|---|---|---|

Weight | Lighter (1.6 g/cm³) | Heavier (2.7 g/cm³) |

Strength | Higher tensile strength (up to 6,000 MPa) | Lower tensile strength (around 572 MPa) |

Stiffness | Stiffer with higher modulus of elasticity | Less stiff |

Thermal Properties | Poor thermal conductivity | Better thermal conductivity |

Cost | More expensive | More cost-effective |

Carbon fiber is 40-45% lighter than aluminum. This makes it good for jobs where weight is important.

Carbon fiber has much higher tensile strength. It can reach up to 6,000 MPa. Aluminum only reaches 572 MPa.

Pick carbon fiber for high-performance needs. It gives better strength-to-weight ratios.

Aluminum costs less and is easier to shape. This makes it good for projects with smaller budgets.

Carbon fiber does not rust. It has great fatigue resistance. It lasts longer in tough conditions.

Aluminum conducts heat better than carbon fiber. It is better for jobs needing fast heat loss.

Think about the environment. Aluminum is easier to recycle. Carbon fiber is often thrown away.

DASEN carbon fiber products give high performance and reliability. They are a strong choice for tough jobs.

Image Source: unsplash

You may want to know which is stronger. Carbon fiber has much higher ultimate tensile strength than aluminum. Carbon fiber can reach up to 6,000 MPa. Aluminum usually only gets to about 572 MPa. This means carbon fiber can take more force before it breaks. Carbon fiber also has a higher yield strength. It resists bending better than aluminum.

DASEN’s carbon fiber uses advanced composite technology. Every batch has high strength and rigidity. The prepreg process lines up each fiber perfectly. This makes the material strong and reliable for tough jobs.

Note: Some people think carbon fiber is always better. But both materials have good uses. You should pick based on what you need for strength, weight, and cost.

You might wonder how they handle impacts. Carbon fiber spreads force across its fibers when hit. This helps stop cracks and sudden breaks. Aluminum bends more easily when hit. It can bend instead of snapping. For high strength and rigidity, DASEN’s carbon fiber is a good choice.

There is a big weight difference between the two. Carbon fiber has a density of about 1.6 g/cm³. Aluminum has a density of 2.7 g/cm³. This means carbon fiber is much lighter. Using carbon fiber lowers the weight of your product. This matters in cycling, cars, and electronics.

Property | Carbon Fiber | Aluminum Alloy |

|---|---|---|

Weight | Lightweight | Heavier than carbon fiber |

Strength | Higher strength | High strength |

Stiffness | Higher stiffness | High stiffness |

Thermal Properties | Excellent heat resistance | Good thermal conductivity |

Cost | Relatively high | Relatively low |

The strength-to-weight ratio is important when picking a material. Carbon fiber gives a better strength-to-weight ratio than aluminum. You get more strength for less weight. DASEN’s carbon fiber has a high strength-to-weight ratio. This makes it great for high-performance needs. Carbon fiber can be up to 45% lighter than aluminum. It still gives more strength and rigidity.

Many engineers want high strength-to-weight and stiffness-to-weight. DASEN’s carbon fiber is made with advanced processes. You get a product that meets strict standards.

Some people think carbon fiber is unsafe or that aluminum is always cheaper and weaker. The best choice depends on what you need.

Both materials are strong, but carbon fiber has a better strength-to-weight ratio and higher tensile strength.

DASEN’s carbon fiber sets new standards for performance and reliability.

Both carbon fiber and aluminum have special properties. If you need a high strength-to-weight ratio, carbon fiber is best. DASEN’s carbon fiber helps you get the right mix of strength, weight, and performance.

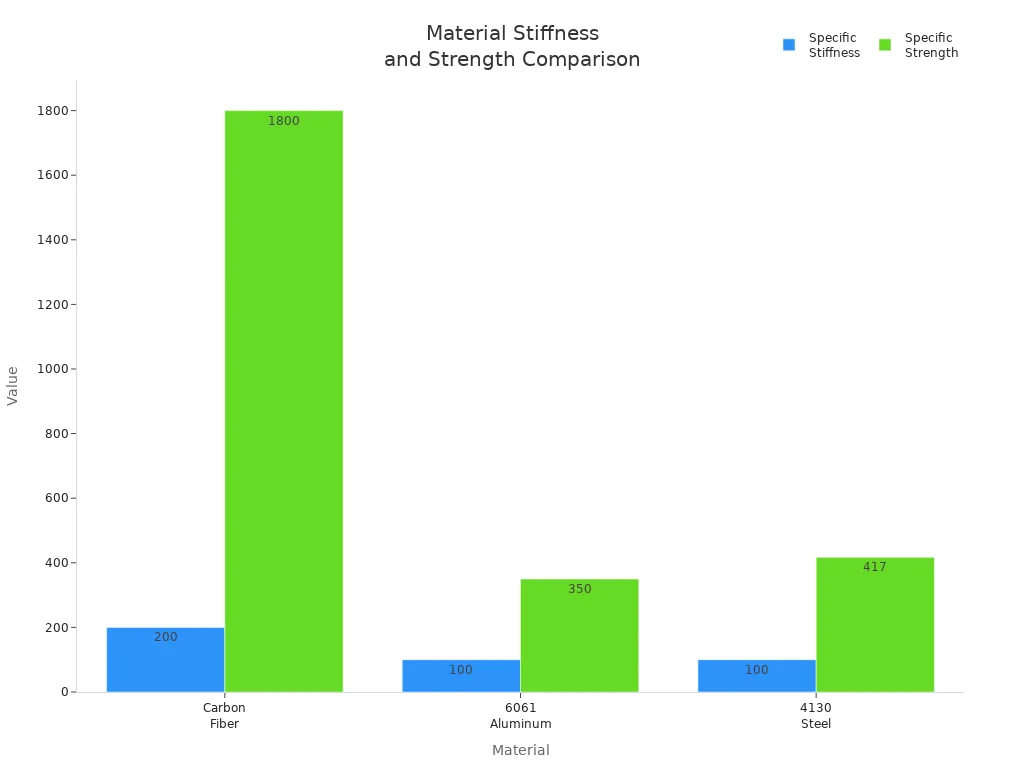

Stiffness is important when you compare materials. DASEN carbon fiber is special because it has high specific stiffness and strength. You can look at the table to see how carbon fiber, aluminum, and steel compare.

Material | Specific Stiffness (MSI) | Specific Strength (KSI) |

|---|---|---|

Carbon Fiber | 200 | 1800 |

6061 Aluminum | 100 | 350 |

4130 Steel | 100 | 417 |

Carbon fiber is twice as stiff as aluminum. This means it bends less and gives you more control. DASEN carbon fiber tubes keep their shape even under stress. This helps you get better results.

Aluminum is more flexible than carbon fiber. You can bend aluminum without it breaking. This makes aluminum good for things that need to bend a little. You can change aluminum parts more easily. Carbon fiber’s flexibility depends on how thick it is, how the fibers are arranged, and the resin used. Thinner sheets bend more. Different fiber patterns change how it acts. The resin can also make it more flexible and help with impacts.

You want your material to last a long time. Carbon fiber is very durable because it does not get tired easily. You can use it for things that get used over and over. Aluminum alloys have a fatigue limit between 90 and 250 MPa. This means aluminum works for many things, but carbon fiber lasts longer. DASEN carbon fiber stays strong even after many uses.

Carbon fiber does not get tired or break down easily.

Aluminum is good for s and other uses, but carbon fiber lasts longer.

You need materials that do not rust or wear out fast. Carbon fiber does not rust or break down. You can use it in tough places and it will last. Aluminum does not rust because of its oxide layer, but it can wear out in saltwater or harsh places. If you use carbon fiber and aluminum together, aluminum can wear out faster because of galvanic corrosion.

Carbon fiber stays strong for a long time.

Aluminum can wear out in tough places.

You should think about how well a material moves heat. Aluminum moves heat very well, at 205 W/m·K. Carbon fiber does not move heat as well, only 5 to 10 W/m·K. Aluminum is good for things that need to lose heat fast. Carbon fiber is better where you need heat resistance and stability.

Material | Thermal Conductivity (W/m·K) | Heat Resistance |

|---|---|---|

Aluminum | 205 | Melts at approximately 660°C |

General-purpose Carbon Fiber | 5-10 | Can withstand higher temperatures without degrading |

You want your product to stay the same size when it gets hot or cold. Carbon fiber almost does not expand at all. This means it keeps its shape very well. Aluminum expands more, which can make things less stable.

Material | Coefficient of Thermal Expansion (CTE) | Dimensional Stability Impact |

|---|---|---|

Carbon Fiber | Near-zero to +8 K-1 | Maintains dimensions effectively under temperature changes |

Aluminum | Approximately 23 × 10⁻⁶ °C⁻⊃1; | Expands significantly, leading to potential instability |

You can trust carbon fiber to stay the same size when temperatures change. This means it lasts longer and does not get stressed.

Tip: Pick DASEN carbon fiber if you need something that lasts, stays stable, and works well when temperatures change.

Carbon fiber is a premium material. DASEN carbon fiber uses advanced methods. You get high strength and steady quality. The process lines up fibers and controls resin. This makes the material strong for tough jobs. You pay more for carbon fiber. It needs special tools and skilled workers. The price shows the value in saving weight and lasting longer. You pick DASEN carbon fiber for top performance and long life.

Tip: Carbon fiber helps lower weight and boost strength. This gives better efficiency in bikes, cars, and electronics.

Aluminum costs less than carbon fiber. Aluminum is easy to shape and cut. Making aluminum parts is quick and simple. You pay less because aluminum is common and easy to handle. Aluminum is a good choice when price matters most. You pick aluminum for a balance of cost and strength.

Material | Average Cost (per kg) | Manufacturing Complexity | Typical Use Cases |

|---|---|---|---|

DASEN Carbon Fiber | High | Advanced | High-performance products |

Aluminum | Low | Simple | Mass-market applications |

You want your products to last long. Carbon fiber repairs need no extra care after fixing. A carbon fiber repair can last up to 20 years. You protect it with ceramic coating or UV wax every few months. You keep it out of the sun by using covers or parking in shade. You store items in cool, dry places to stop damage.

Carbon fiber spreads stress evenly. This lowers weak spots. Carbon fiber parts resist cracks and bending from repeated use. With good care, carbon fiber car parts can last as long as the car. Research shows carbon fibers can stay strong for over 50 years.

Aluminum needs regular checks for rust and wear. You may need to replace aluminum parts more often in tough places. Aluminum is easier to fix but may not last as long as carbon fiber in hard jobs.

Carbon fiber repairs last longer and need less care.

Aluminum repairs are easy but may need more checks.

Note: Pick DASEN carbon fiber for durability, low upkeep, and steady performance over time.

Image Source: pexels

Carbon fiber tubes are changing how bikes feel. DASEN carbon fiber tubes make bikes light and strong. The strength-to-weight ratio is much higher than aluminum. Carbon fiber frames stay stiff and do not bend easily. You feel less shaking when you ride. Carbon fiber tubes help you ride longer without getting tired. Your bike lasts through many rides because of better fatigue resistance.

Carbon fiber bike frames are 40–60% lighter than aluminum.

You feel less shaking, so your ride is smoother.

Your bike stays strong for a long time.

Carbon fiber tubes cost more, but they work better.

Carbon fiber handlebars help you steer better. Carbon fiber wheels help you speed up faster. A carbon fiber seatpost makes your ride more comfortable. A carbon fiber fork helps you steer well. DASEN carbon fiber tubes make bikes fast and dependable.

You pick aluminum bikes for a good price and strength. Aluminum frames are easy to shape and fix. Aluminum is heavier than carbon fiber tubes. You feel more bumps on rough roads. Aluminum bends more, so it is less stiff. You pick aluminum bikes for a lower price and easy care.

Car makers use carbon fiber tubes to make cars lighter. Replacing steel with aluminum cuts weight by 30–40%. Carbon fiber tubes save even more weight. Lighter cars go farther on less energy. High-performance cars get faster with carbon fiber tubes.

You can cut weight by up to 50% compared to steel.

Lighter cars use less fuel and handle better.

Carbon fiber tubes are used for strong, light car parts.

Carbon fiber tubes are used for strong car parts. They have a great strength-to-weight ratio. Carbon fiber tubes last long and do not wear out fast. They are used in car bodies, frames, and inside parts. Aluminum is picked for big jobs because it is cheap and easy to shape. Carbon fiber tubes are used for high-performance cars.

Carbon fiber tubes make electronics lighter. They help lower the weight of parts. Devices become stronger and last longer. Carbon fiber tubes help phones and tablets work better.

Carbon fiber tubes help store energy and manage heat. They make a network that moves heat well. This helps store more energy and cool things down. Carbon fiber tubes make products lighter and more efficient.

Benefit | Carbon Fiber | Aluminum |

|---|---|---|

Weight | Lighter than aluminum and copper | Heavier than carbon fiber tubes |

Strength | High strength and stiffness | Moderate strength |

Electrochemical Properties | Enhances performance in energy storage | Standard performance |

Carbon fiber tubes are used in batteries and computers. They help products last longer and work better. Carbon fiber tubes help you build things that are strong and efficient.

Tip: Pick DASEN carbon fiber tubes if you want high strength, low weight, and good performance.

You want the best material for tough jobs. You need to see how each material works when things get hard. Carbon fiber is great for high-performance engineering. People use it in racing bikes, s, and cool electronics. Carbon fiber can be up to 40% lighter than aluminum. It gives you high strength and stiffness for its weight. You can make products that are both light and strong.

Carbon fiber is the top pick when weight matters most. It does not get weak after many uses. Carbon fiber keeps its strength for a long time. DASEN carbon fiber is used when you need something strong and reliable. It meets strict rules and lasts longer.

Aluminum is good when you need to handle bumps and shakes. You pick aluminum for parts that must take hits. Aluminum is easy to shape and make into parts. You use aluminum when you want to save money and still get good results.

Carbon fiber is best for saving weight and being stiff.

Aluminum is good for taking hits, costing less, and being easy to shape.

Carbon fiber parts can be up to 40% lighter than aluminum ones.

Aluminum is better at handling bumps and shaking.

Carbon fiber stays strong after many uses if made well.

Aluminum gets tired faster than carbon fiber.

You need to pick the right material for your project. You get the best results when you choose based on what you need for high performance.

You want to get the most for your money. You compare the price of carbon fiber and aluminum. Carbon fiber costs more because it is made with special methods. You pay more for better strength and long life. You use carbon fiber when you want the best results.

Aluminum is cheaper for making lots of parts. You pick aluminum when you need to save money. Aluminum is easy to recycle and shape. You get good strength for less money.

Criteria | Carbon Fiber | Aluminum |

|---|---|---|

Weight Reduction | Best for important weight savings | Not as good for light designs |

Specific Strength/Stiffness | Very strong and stiff for its weight | Medium strength, same in all directions |

Fatigue Resistance | Stays strong after many uses | Needs care to last long |

Corrosion Immunity | Does not rust easily | Can rust if not treated |

Cost Sensitivity | Costs more but worth it for top results | Cheaper for making many parts |

You need to know what your project needs. You look at how the material acts with heat, electricity, and chemicals. You check if it works with how you make things.

You care about the t in 2026. You want to use materials that help the Earth. Aluminum can be recycled 90% of the time. Recycling aluminum saves 95% of the energy compared to making new aluminum. Aluminum is easy to recycle and use again. This means less harm to the environment and following the rules.

Carbon fiber-reinforced polymers are only recycled about 30% of the time. Carbon fiber is hard to recycle. The recycling process uses more energy and can make the material weaker. A lot of carbon fiber ends up in landfills. Making carbon fiber uses a lot of energy. It also makes a lot of CO₂ and lets out harmful chemicals.

Aluminum can be recycled 90% of the time.

Carbon fiber-reinforced polymers are recycled only 30% of the time.

Recycling aluminum saves 95% of the energy needed to make new aluminum.

Recycling carbon fiber uses 40% more energy than making new aluminum.

Making carbon fiber uses a lot of energy.

The process makes a lot of CO₂.

Harmful chemicals from making carbon fiber can hurt people and nature.

Carbon fiber is hard to recycle and often goes to landfills.

Recycling carbon fiber uses a lot of energy and can make it weaker.

You should pick materials that can be recycled. You want to lower harm to the t. You make choices that help the Earth and follow the rules.

Tip: You get the best results when you pick your material based on your project, your budget, and how much you care about the t.

You notice carbon fiber is lighter and stronger than aluminum. Carbon fiber costs more, but it works better and lasts longer. Aluminum is cheaper and easy to shape, but it is heavier and can rust. DASEN’s carbon fiber has high thermal conductivity and strong quality checks. If you want the best strength and trust for tough jobs, pick carbon fiber. If you need to save money, aluminum is a good choice.

Aspect | Carbon Fiber | Aluminum |

|---|---|---|

Strength | 2–5 times stronger | Weaker |

Weight | Half the weight | Heavier |

Cost | Lower |

Tip: You can count on DASEN for advanced carbon fiber in 2026.

Carbon fiber is stronger because its fibers go one way. This helps it take more force before breaking. Products that need to be strong and light work better with carbon fiber.

Yes, carbon fiber is lighter. Its density is about 1.6 g/cm³. Aluminum’s density is 2.7 g/cm³. You save weight when you pick carbon fiber for your project.

You can use DASEN carbon fiber tubes in bikes and cars. These tubes are strong and light. They help parts last longer and work better in cycling and cars.

Aluminum moves heat faster than carbon fiber. Carbon fiber keeps its shape when it gets hot or cold. You pick carbon fiber when you want things to stay strong and stable.

Carbon fiber costs more because it uses special materials and methods. You get better strength and less weight. Aluminum is cheaper and works for many things, but carbon fiber gives top results.

Carbon fiber parts can last for many years. If you take care of them, they stay strong and do not get weak. DASEN carbon fiber gives you value for a long time.

Aluminum is easy to recycle and gets used again a lot. Carbon fiber is harder to recycle and not as common. You should check if your area recycles carbon fiber.

You pick DASEN carbon fiber for its strength, light weight, and good quality. DASEN uses new technology and checks every product. You get what you need for bikes, cars, electronics, and more.