English

Views: 1 Author: Site Editor Publish Time: 2017-09-17 Origin: Site

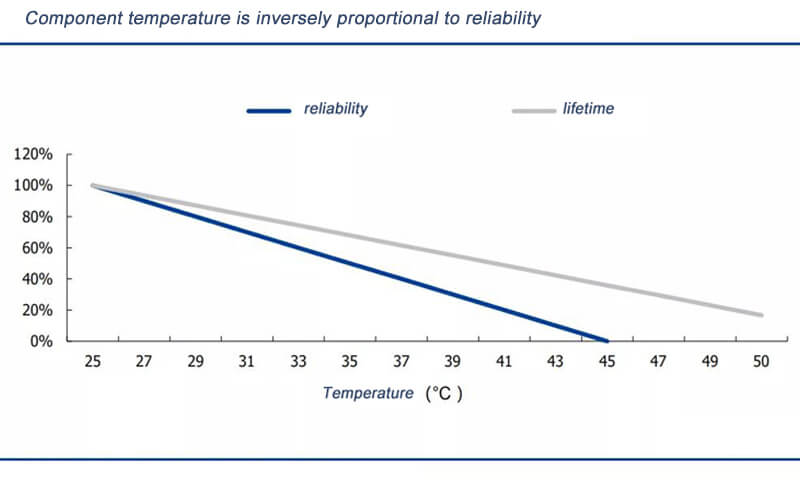

Thermal graphite sheet has excellent physical characteristics, and has become the best choice of heat dissipation material for electronic products. With the high frequency and high speed of electronic devices and the denseness and miniaturization of integrated circuits, the advancement of MEMS (Micro Electro-Mechanical System) technology, electronic components the total power density of the device has increased significantly while the physical size has become smaller and smaller, and the heat flux density has also increased. Tests have shown that for every 2 ° C increase in temperature of electronic components, the reliability decreases by 10%; The service life is only 1/6 of the temperature rise of 25 ℃. Traditionally, the high thermal conductivity of copper and aluminum materials directly dissipates heat, or it is difficult to meet the existing needs with silica gel, fans, and liquid cooling. The graphite materials with high thermal conductivity, the characteristics of anisotropy, low density and small volume, which greatly reduce the cost, are the best heat dissipation materials at present.

The market size of thermal graphite materials is growing rapidly. Under the development trend of ultra-thin, intelligent and multifunctional consumer electronics, the proportion of graphite for thermal applications such as mobile phones is rapidly increasing. According to data from Credence Research, the global thermal interface material market scale in 2015, it was USD 774 million, which is expected to increase to USD 1.711 billion in 2022, with a compound annual growth rate of 12.0% during 2015-2022. We estimate that the potential market size of graphite thermal conductive materials is RMB 8.264 billion (only smartphones and tablets are measured) (Notebook, notebook computer, and wearable devices) .The future growth of the graphite cooling market will mainly rely on new application areas, especially in automotive electronics, 5G and other fields, and other high-power LED lighting, circuits, laser weapons, etc. There are also cooling needs in areas such as high-integration systems.

The total power density of electronic components has increased significantly, and the demand for heat dissipation has soared

Electronic products generate heat during operation, which will directly affect the performance and reliability of electronic products. With the high frequency and high speed of electronic devices and the denseness and miniaturization of integrated circuits, MEMS (Micro Electro-Mechanical System) technology With the progress, the total power density of electronic components has increased significantly, but the physical size has become smaller and smaller, and the heat flux density has also increased. Tests have shown that for every 2 ° C increase in temperature of electronic components, reliability decreases by 10%; temperature rise the life at 50 ° C is only 1/6 of the temperature rise at 25 ° C. The high temperature environment affects the performance of electronic components, which requires more efficient thermal control, and the thermal conductive material is mainly used to solve the heat of electronic equipment. Management issues.

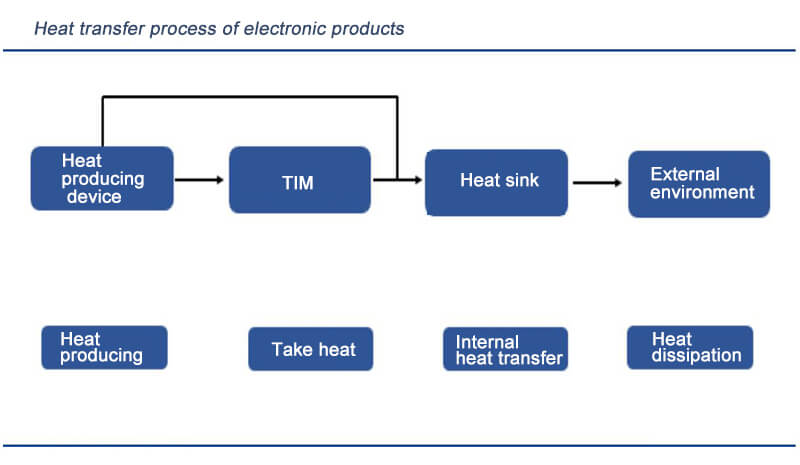

Heat conduction, convection, and radiation are the three basic ways of heat transfer. In the process of heat transfer, depending on the structure of the heat sink, heat transfer is combined with heat conduction, convection, and radiation. The principle of heat dissipation in electronic products is through the thermal interface. The material takes heat from the heat-generating device to the heat sink, and finally dissipates the heat to the external environment, reducing the temperature of the electronic product.

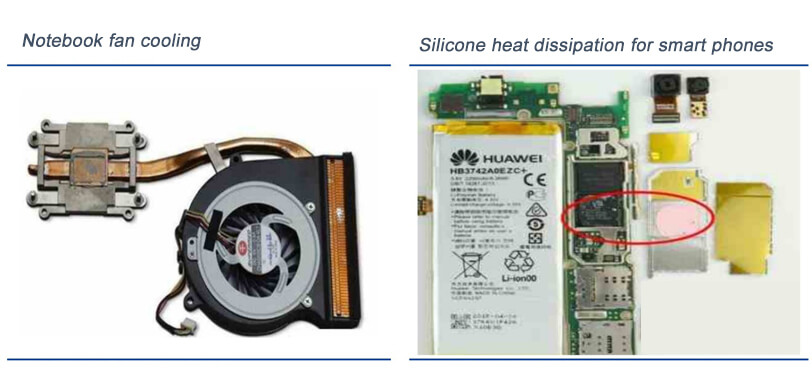

Miniaturization of electronic products, thermal graphite becomes the best choice

It is difficult for traditional heat dissipation methods to meet the existing demand. The heat dissipation problem has always been a hot spot and a difficult point in the consumer electronics industry. Thermally conductive materials are mainly used between the thermal interfaces of the system. The thermal interface material replaces non-heat-transmitting air, which reduces the thermal resistance through the thermal interface and improves the heat dissipation efficiency of semiconductor components. The industry is also called "thermal interface material". In the past, the heat dissipation of consumer electronics products mainly used copper and aluminum. The high thermal conductivity of the manufacturing material directly dissipates heat, or cooperates with silica gel, fans, and fluid to form a heat dissipation system, which takes away the heat emitted by the device.

Under the development trend of consumer electronics towards ultra-thin, intelligent and multifunctional, the internal space of products is becoming more and more narrow, and it is difficult to meet the demand only by using copper, aluminum materials and silica gel. Thermal graphite has excellent heat dissipation effect, and the superimposed cost is declining. We think that the thermal graphite sheet has become the best choice for the heat dissipation material of electronic products.

Miniaturization and high power of electronic components

Taking Intel chips as a representative, we can see that the chip development trend is from single-core to multi-core, low frequency to high frequency, low thermal design power to high thermal design power. General thermal design power is mainly used in CPU, CPU thermal design functions The consumption value corresponds to the maximum heat dissipation that the final version of the series of CPUs may reach at full load (theoretically, the CPU utilization is 100%). The heat sink must ensure that the processor temperature is still within the design range when the processor TDP is maximum.

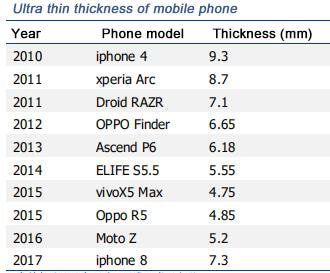

Laptops and smartphones are becoming lighter and thinner. Consumers prefer thinner and lighter products, and we can see that the proportion of thin and light notebooks is continuously increasing, and smartphones are becoming thinner and thinner. With integrated circuits Chips and electronic components have been shrinking in size, but their power density has increased rapidly, and heat dissipation has become an urgent problem for electronic equipment.

Excellent graphite performance

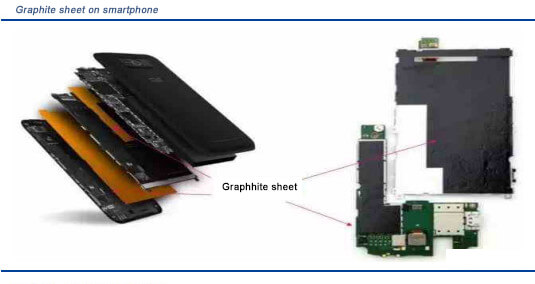

Thermal graphite film is also called thermal graphite film, thermal graphite sheet, graphite thermal film, etc. It is a new type of thermal material, with high thermal conductivity, anisotropy, low density and small volume. It has unique grains. Orientation, uniform heat conduction in both directions, and high thermal conductivity, is made of a highly oriented graphite polymer film. The sheet-like layer structure can be well adapted to any surface, shielding heat sources and components while improving consumer products Performance of electronics.

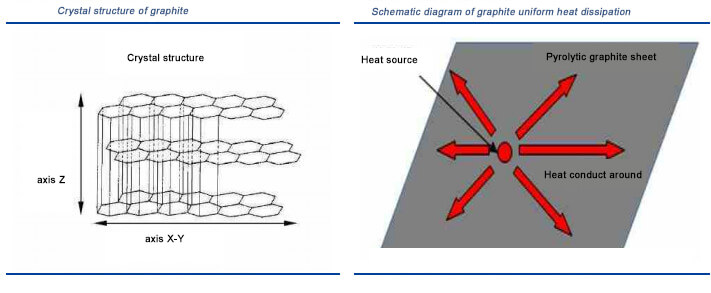

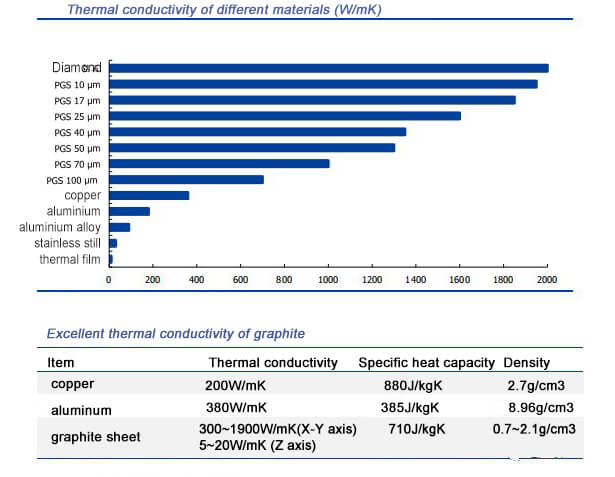

The research found that graphite crystals have a hexagonal planar network structure, which has the characteristics of high temperature resistance, small thermal expansion coefficient, good thermal conductivity, stable chemical properties, and large plasticity. The unique crystal structure of graphite makes its heat transfer mainly concentrated in two directions : XY axis and Z axis. The thermal conductivity of its XY axis is 300 ~ 1,900W / (m · K), while the thermal conductivity of copper and aluminum in the XY direction is only between 200 ~ 400W / (m · K), so Graphite has better heat conduction efficiency and can transfer heat faster. At the same time, the thermal conductivity of graphite in the Z axis is only 5 ~ 20W / (m · K), which almost plays the role of heat insulation. Therefore, graphite has Good soaking effect can effectively prevent local overheating of electronic products. From the perspective of specific heat capacity, the specific heat capacity of graphite is equivalent to that of aluminum, which is about 2 times that of copper, which means that after absorbing the same heat, the graphite temperature rises only by copper. Due to the outstanding properties of graphite in thermal conductivity, it can replace traditional aluminum or copper heat sinks and become an excellent material for heat dissipation solutions.

Under the development trend of consumer electronics towards ultra-thin, intelligent and multifunctional, the internal space of products is becoming more and more narrow, and it is difficult to meet the demand only by using copper, aluminum materials and silica gel. The special crystal structure of graphite makes its thermal conductivity mainly concentrated in the horizontal direction (ab ), and in the vertical direction of graphite crystals, graphite has low thermal conductivity and good thermal insulation properties, so graphite crystals have good horizontal thermal conductivity and vertical resistance. The thermal effect is a good thermal conductive medium. Compared with other materials, graphite has excellent thermal conductivity. Because graphite has good thermal conductivity and can achieve rapid heat transfer, it is often used as a thermal conductive device in the cooling system of electronic products. Low-end mobile phones generally use silicone grease for heat dissipation. There is a price advantage. A mobile phone costs about 0.32 RMB, but its thermal conductivity is low, which is suitable for price-sensitive customers. Mid-to-high end machines mainly use thermal graphite, and the cost of each mobile phone is about 3.3 Yuan, compared with the low-end mobile phones, the cost of use is 10 times.

One of the core issues in the development of consumer electronics is how to reduce the peak temperature of electronic components. The main way to increase the heat dissipation effect of graphite heat dissipation film: The heat is quickly transmitted to the chassis and frame through the ; the surface enhances the infrared radiation effect; and expands the heat Area, quickly dissipate heat dissipation points. At present, the mainstream heat dissipation film materials are mainly divided into three categories, namely natural graphite heat dissipation film, artificial graphite heat dissipation film, and Nano-carbon heat dissipation film. Each of the three types of heat dissipation films has advantages and disadvantages, and is currently widely used in various Branded mobile phones and other consumer electronics.